When you install an industrial floor, you are expecting it to last for the years ahead. They are meant to be durable and long-lasting options that can withstand even the greatest amounts of foot traffic or wear and tear. Unfortunately, this might not be the case if your contractor isn’t meticulous about surface preparation prior to the installation. An improperly prepared subfloor could cause a number of issues that result in failure of the floor rather quickly.

Many different issues can arise from improper preparation, but one stands out among the others. Let’s take a closer look at one of the major failures that can occur without the proper surface preparation.

Bond Failure

The most significant issue that can result from improper surface preparation is a bond failure. This happens when the finish on the floor begins to delaminate from the surface of the concrete. You might begin to notice it through small chips, areas where the finish begins to peel, or separation between different coatings. It ruins the smooth appearance of your floor and the professional look of your industrial coatings such as polished concrete or epoxy.

In addition to being aesthetically unpleasing, bond failure can also become a hazard for the workplace. It can trap dust, dirt, and bacteria in these areas where the finish has been removed from the surface. This makes it more difficult to clean, and it also makes it into a trip hazard. Many industrial businesses install these seamless floors because they have a grip that makes slipping rather difficult, but that may no longer be the case when the finish starts to peel.

How Can We Correct It?

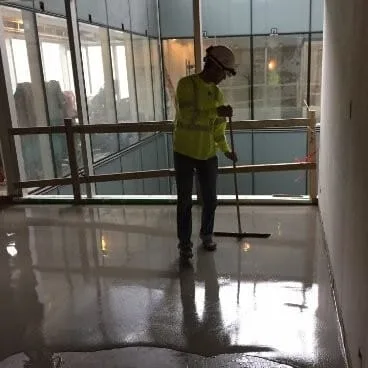

The best way to prevent bond failure is to prepare the surface the right way. You must begin by repairing any areas of the concrete substrate that require patching or grinding. Any imperfections in the floor will be magnified when the finished coating is applied. You might also want to apply a simple primer to the floor to help increase the potential for a good bond. These products should be water-based or solvent-based primers instead of traditional paint primers. They are specifically designed for this type of application.

You also want to make sure that you are providing the right texture or profile to the concrete prior to application of the finish. Depending on the unique slab, you may want to use diamond grinding, shot blasting, or scarification to improve the finished texture of the floor. This texture makes it much easier for your finish to adhere to the concrete. It also helps to remove any chemicals, bacteria, grease, or oil that could have been on the substrate and could prevent finish adhesion.

Preventing bond failure is far easier than attempting to correct it later on. You need to make sure that you are working with experienced professionals to apply the appropriate concrete finishes to your next project. TCF West can help you figure out just what your project needs to be successful!