There’s no simple answer to the question posed in the title. When you look at something like roofing, it’s fairly easy to figure out a lifespan. Roofs aren’t used, so to speak – there’s no real variance in how much foot or vehicle traffic a roof is going to get. Every roof in a given area is going to be subject to about the same weather conditions, so it’s easy to estimate how long a given roofing material will last.

There’s no simple answer to the question posed in the title. When you look at something like roofing, it’s fairly easy to figure out a lifespan. Roofs aren’t used, so to speak – there’s no real variance in how much foot or vehicle traffic a roof is going to get. Every roof in a given area is going to be subject to about the same weather conditions, so it’s easy to estimate how long a given roofing material will last.

Unfortunately, that’s not the case when it comes to epoxy flooring. We could tell you that an epoxy coating is likely to last about 10-15 years for commercial purposes, and about 25-30 years for residential garage use. That’s probably not a bad approximation, but there are a lot of factors to consider:

The quality of the installation and epoxy

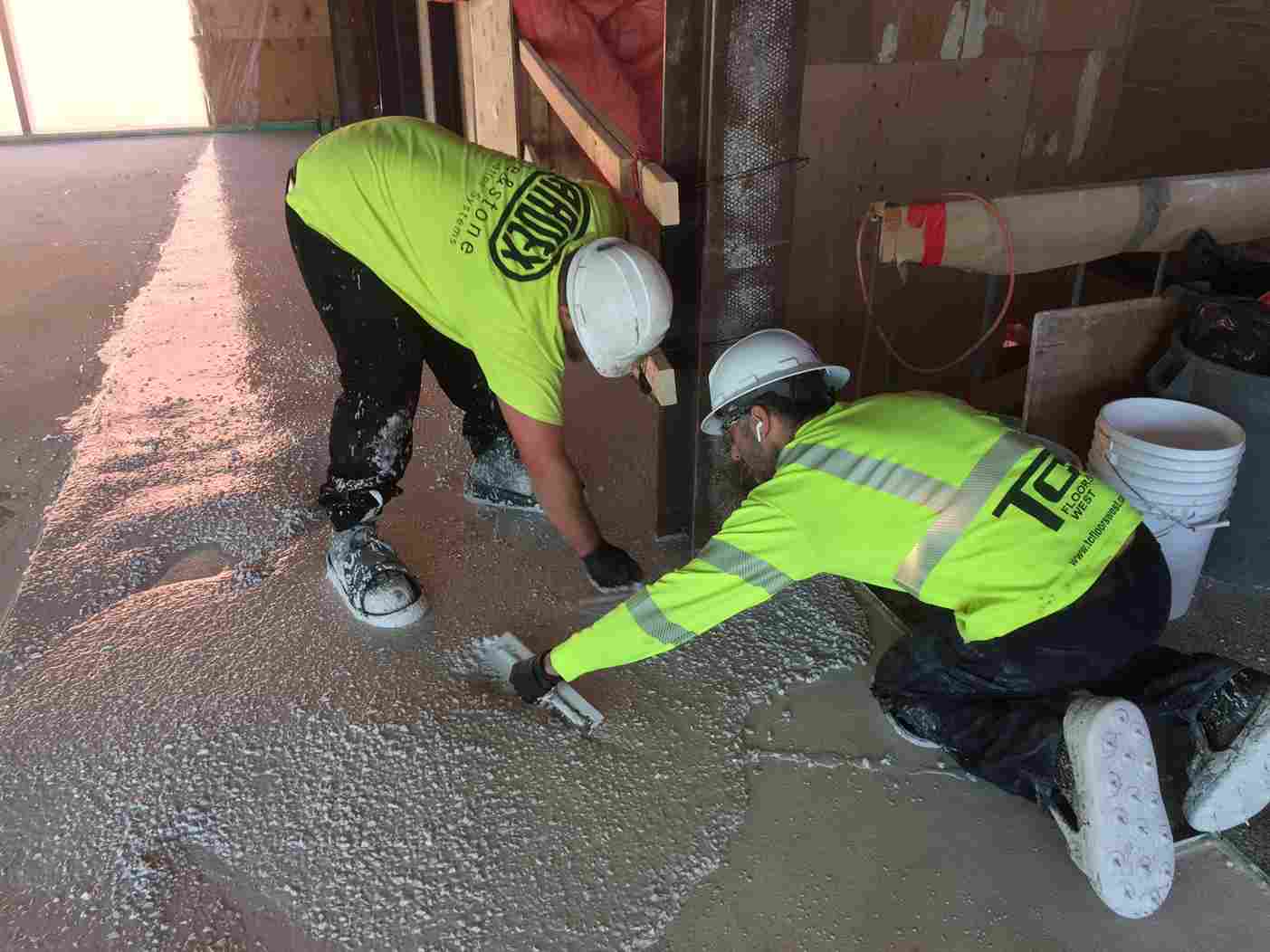

To no one’s surprise, a ‘do-it-yourself’ epoxy kit will not last you nearly as long as a professionally installed epoxy coating. The DIY kits have inferior epoxy, to begin with – pros use 100% solids epoxy, which is too challenging for most hobbyists to install. Second, the pro’s are buying direct from the largest and most established suppliers of resin. This is very different from materials found in hardware stores and even specialty distributors in terms of quality and performance.

Then there are all of the factors you have to consider during the installation – the concrete surface prep (profiling) the cleanliness and moisture levels of the substrate, how even the coating is, and whether or not additives were used properly. That’s only scratching the surface, too – epoxy installation is complex, and a professionally done installation will last you a lot longer.

The amount and type of traffic the flooring gets

An epoxy coating on a residential staircase gets virtually no foot traffic. That coating is going to last you decades, because there’s no real wear and tear happening.

On the flip side, epoxy coating on a warehouse floor isn’t going to last nearly as long. There’s heavy machinery contributing to wear and tear every day. Of course, if your flooring contractor knows what they’re doing, they’ll use a much thicker epoxy coating for industrial or warehouse settings. As well, the professionals may install different types of coatings in different parts of your facility. For example , drive aisles versus turning lanes….turning lanes take far greater abuse than vehicles going in a straight line!

Its level of exposure to UV radiation

UV radiation can cause the binding agents in epoxy to deteriorate. However, industrial flooring professionals have access to UV inhibited resins that make the colors stable over time and even for exterior use.

How well you maintain it

One of the biggest advantages to epoxy flooring is that it can stand up to pretty much anything – it’s extremely durable and resistant to most chemicals. It’s also relatively easy to maintain, but if you totally neglect it, your epoxy flooring can end up getting damaged. Fortunately, you don’t need to do a whole lot to keep your coating clean.If you’re interested in getting epoxy floors, get in touch with us. We’re an epoxy flooring contractor in Winnipeg, and we can handle installation, repairs, and any other epoxy coating services you need.