Epoxy (ep – ox – y)

/iˈpäksē/

noun: an adhesive, plastic, paint, or other material made

from a class of synthetic thermosetting polymers containing epoxide groups.

If you’ve read up a bit on our website, or you’ve talked to some people you know about flooring and concrete, you’ve probably seen or heard the word “epoxy” more than once. Like many people, you might have just nodded your head, pretending you know exactly what it is and what it’s used for on job sites. Meanwhile, you’ve got no clue in the world what the word means, much less how it’s going to help with your project. Trust us, you’re not alone.

The Very Basics

Epoxy is one of many forms of ‘resinous flooring‘. Other types of resins we use are ; mma’s, polyaspartics, urethanes, and polyurethane concrete. Think of it as the last step in your flooring project. Once this coat dries, the floor is ready to handle whatever you need it to: vehicles in a garage, heavy furniture, industrial storage, and so on. It’s a popular coating and sealant for a few reasons:

- First and foremost, it protects against moisture/chemical attack, which is the most common and expensive problem that customers face when dealing with concrete floors. If they aren’t properly protected, they are a costly fix.

- It protects against mechanical damage. This kind of damage includes impact, cuts, scratches, and abrasions.

- It is UV stable. This means that light sources, indoor or outdoor, won’t fade the finish and look of your floor.

- It’s seamless. You won’t find sections of the top coat rolling up or letting dust, dirt, or moisture into the concrete, and you’ll never see an unsightly seam down the middle of your floor.

- Epoxy is slip-resistant. Although the finish often appears somewhat glossy, the floor will be suitable for just about anything, with no need for slip-and-fall concerns.

And… There’s More…

Epoxy/Resinous-based coatings are ideal for any size floor in any space. They contain little or no volatile organic compounds (VOC). This means less health hazards in closed spaces. The 100% solids that we use also have an unparalleled rapid drying time.

How Does That work?

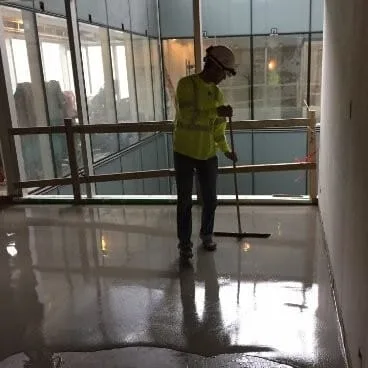

Unlike other coatings or sealants, resinous flooring maintains the same level of thickness from the time they are applied wet to the time the coating dries. Depending on the project you have in mind, we may suggest only one coat, but if we suggest a second coat, your wait time won’t be astronomical. Either way, these resins will keep your project costs down because you will know from the onset that we won’t be applying layer upon layer of slow-drying protectants to your concrete, eating up your time and money.

Make Your Project Unique

For industrial work and storage spaces, or for a more uniform look, you might want to go for a basic, clear epoxy. On the other hand, resins come in a variety of pigments and are easy to customize to fit your space. For something truly unique, we can include a broadcast media, like coloured chips or coloured quartz, throughout the flooring or even a metallic pigment!

There you have it. Now that you speak the language of the project professionals, you can be confident that your next concrete flooring endeavour will turn out exactly the way you planned.